CNC Punch Forming Capabilities

The following list shows some of the possibilities of forming that we can accomplish in our CNC Punch. These capabilities often eliminate costly secondary operations or streamline assembly of multiple components.

Tapping Tool

The tapping tool creates fast, accurate, high precision threads in the punch press on any programmed location on the sheet. The tool streamlines punching applications, allowing fabricators to eliminate costly, inaccurate and time-consuming secondary operations such as manual tapping, clips or other hardware.

The tapping tool forms threads in the sheet metal rather than cutting them, which results in stronger threads with a higher tensile strength than cut threads. The tool is capable of tapping threads in thinner materials when an extrusion is formed first.

Rolling Offset

The Rolling Offset tool quickly creates offsets in any contour, starting or ending anywhere on the sheet. Straight or curved offsets are seamlessly formed into the sheet metal. In some cases thinner materials can be used as the offset tool can add a stiffening feature to the part. This process is more commonly known as a jog bend in the pressbrake realm. Jog bends typically require their own special pressbrake tools and are often a separate setup and operation when processing the part. Performing this operation in the punch saves valuable process time.

Half Shear

The Half Shear is an easy-to-use tool that allows you to put in shear buttons (material is sheared approximately half way out of the base material). Round Half Shears make quick and easy locators as well as alignment points for secondary operations such as spotwelding and welding. Rooftop half shears give you greater height protrusion from the metal which assists in picking up the locator on the sheet.

Louver

Louvers can be added to your part during the punch process eliminating expensive secondary operations or hard tooling. Some louvers can be made to any required length and can be varied within the same part.

Coin

Coining operations on the punch press save valuable time by replacing these secondary operations of drilling countersinks and counterbores.

Bridges

Bridge type lance and forms can be used for shear stops, locators, card guides, dividers, ventilation and wire tie downs.

Dimple

Dimple tools create a recess or a protrusion used for creating stand-offs, spacers, large countersinks and locks for nuts.

Extrusion

Extrusions can be used in a broad spectrum of applications, such as self-tapping screws, cooling tube holders, air flow applications or tread plate.

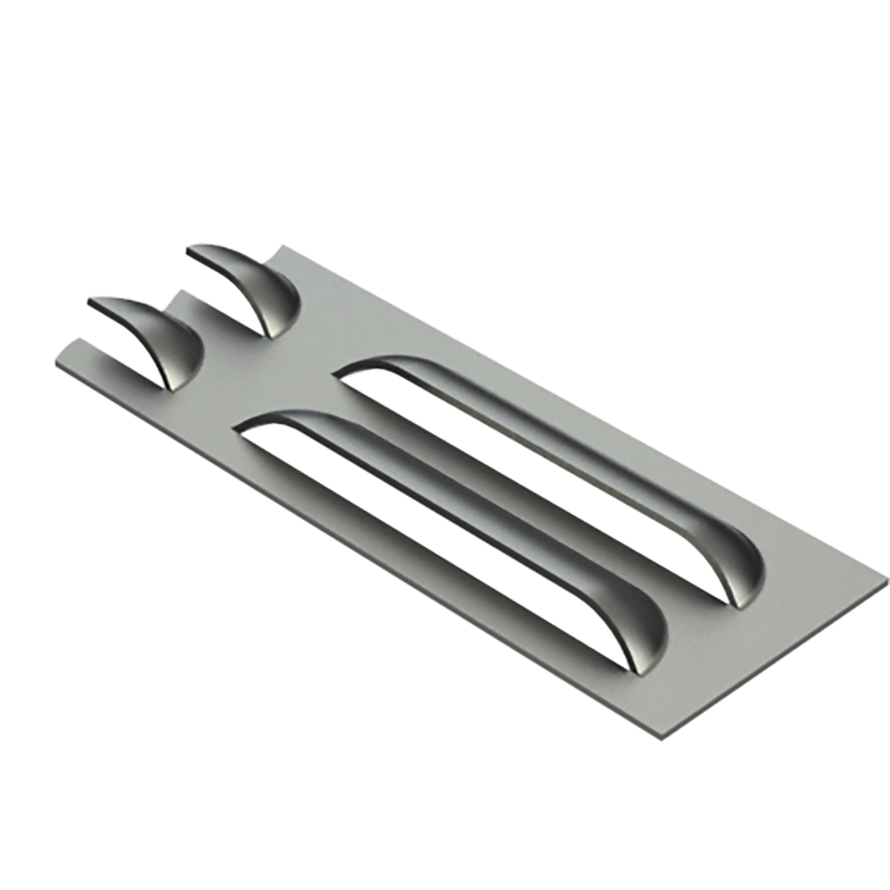

Lance and form

Lance and Forms are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear tabs, wire harnesses and clip attachments.

Hinge Tool

With Hinge tools, you can eliminate costly hardware, fitting and line-up assembly. They allow you to fabricate complete panels with their own integrated hinges. Depending upon your application, a hinge can be completed on the edge or in the middle of the sheet.

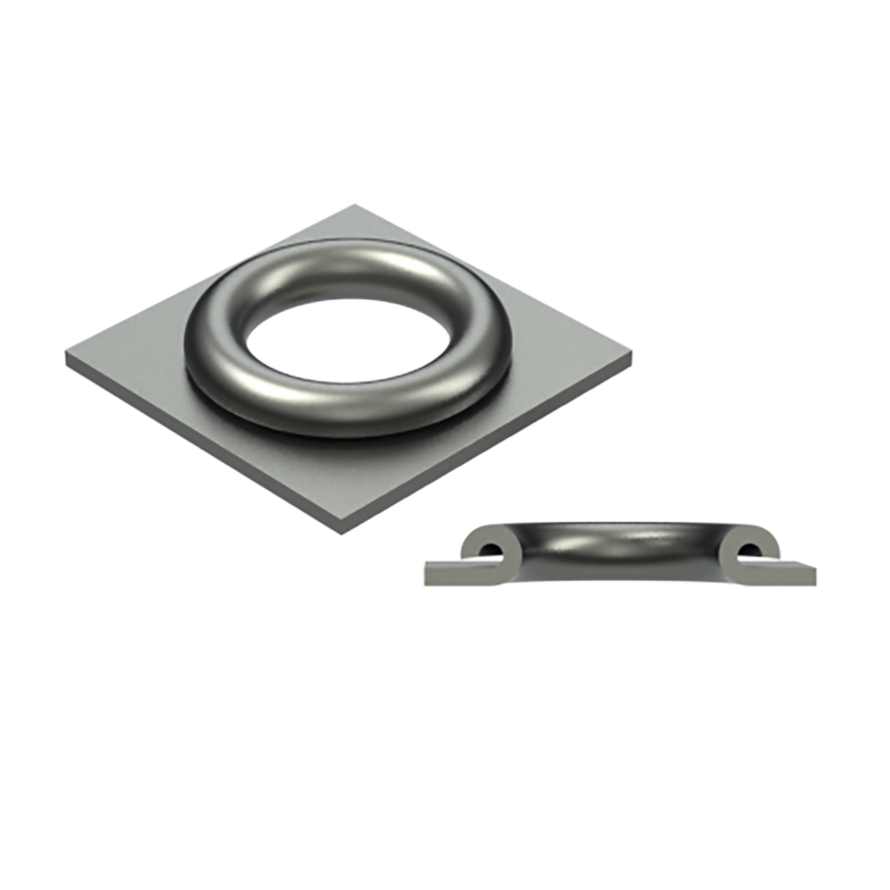

Rollover Tool

The Rollover or Curling tool can be used in many applications such as hand holds, wire feeds and grommets. This tool reduces costly secondary operations and handling.

Triple Lock Tool

A Triple Lock Tool creates a form that is used to secure nuts and bolts in your material.